Kit Aircraft

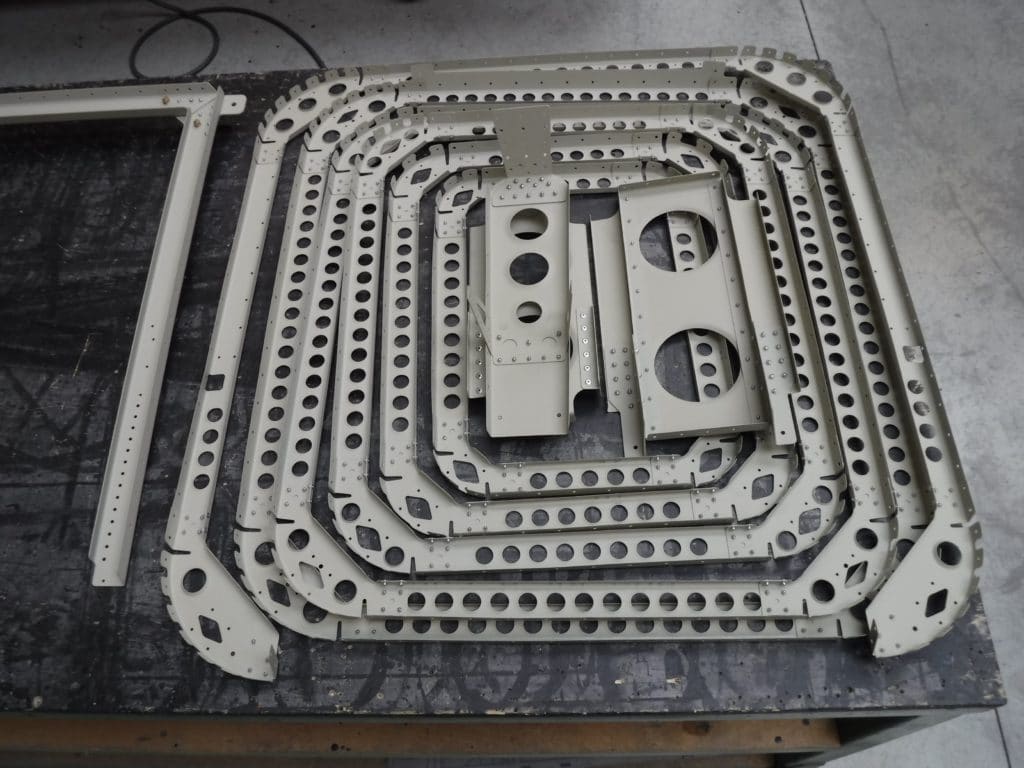

All kit parts are produced by serial production and laser-cut, allowing for perfect interchangeability of the spare parts. All the aluminum skins are cut to size, pressed or shaped, drilled and ready to be riveted using the rivets supplied with the kit.

Take advantage of our Kit building experience !

We have previously assembled numerous Aircraft and continue to do so on an ongoing basis. If you would like to avail of our services please get in touch here.

Estimated building time without painting and upholstery work

110 to 350 hours (Savannah) or 400 hours (Ventura)

With painting and upholstery work – 600 hours

First time builders can expect a build time of between – 700 – 800 hours

Aircraft Kit Contents

The aircraft kits are broken out in to phase to ease budgeting and space when building. We can help you customise your order to suit any additional features or options you wish to select, or even an engine upgrade or additional cockpit panel instruments.

All the parts are produced by serial production on CNC and laser-cutting machines. All the aluminum skins are cut to size, bent or pressed, drilled and a ready to be riveted using the supplied rivets and rivet gun. Only a little deburring before fitting, or some alodine coating will be requiring prior to fitting.

Any parts that need to be solid riveted such as the wing spars or some parts of the fuselage are supplied pre-built in order to simplify the overall build process.

All cables are pre-cut to the correct length and crimped with thimbles using certified NICO press equipment.

This includes:

- The Fuselage.

- Wings with flaperons. Struts with their aerodynamic profile pre drilled for perfect alignment.

- Two wing tanks 36 liters (9 Gallons) each, a reserve tank with ball-cock reserve indicator, condensation drain, fuel tap and tubing.

- Tail with rudder and elevators with trim, servo and wiring harness.

- Tricycle landing gear, disc brakes, tyres and tubes.

- Dual rudder pedals, dual throttles, center Y stick (yoke), flag lever.

- All cables with turnbucklets, guides and mounting brackets. All cables have already been precut to the correct length and crimped with thimbles using certified NICO press equipment.

- All AN screw bolts, nuts and washers and locking wire.

- All rivets, the rivet gun, clecos and cleco pliers.

Estimate around 150 hours to complete this phase, exclusing any paintwork.

This includes:

- A Rotax 912 engine mount and related connections.

- The full engine cowling.

- Water radiator and hoses with a steel spiral core, oil radiator with streel reinforced oil tubes, all required NORMA and ABA clamps.

- Cockpit heating system.

- Complete fuel tubing and related parts, including the filter, electric fuel pump with a distributor for the included fuel pressure gauge, fuel return lines to the wing tanks, rubber stratified fuel hoses, all required NORMA clamps.

- Full naviation and engine instruments. Including an air speed indicator, three point altimer, vertical speed indicator, slip/skid indicator, compass, tachometer (Hobbs), voltmeter, oil pressure and temperature gauges, fuel pressure gauge, cylinder head temperature, inside cowling and outside air temperature gauge.

- Complete electrical wiring harness, keyed master, dry charge battery with a battery charge light, two thermo breakers, full switches for all of the electrical systems, fuel reserve light with test button, landing and cabin lights, elevator trim servo.

- Double padded high back seats.

Estimate another 150 hours to complete this phase, more if you are upgrading your panel or the interior.

This includes:

- A Rotax 912 engine.

- Exhaust with stainless steel silencer.

- Voltage regulator and oil tank.

- Propeller and spinner.

Estimate around 50 hours to mount the engine and connect up the final components before test flying begins.

Purchase options

You can purchase the kits in stages, either purchasing everything at the beginning so that you have all the parts ready to complete your build at your own pace. Or you could purchase Kit 1, built the main structure, then add in Kit 2 to complete the cockpit and internals. Then purchase Kit 3 to complete the firewall forward, or source your own new or second hand Rotax 912, exhaust, propeller and spinner to be ready to test fly your plane.

We have build assistance options to help you throughout all stages of the build, and service options for once you start enjoying flying your brand new airplane.

Kit building

Serially produced parts arrive ready to be assembled. Only very minimal preparation is needed, with some minor deburring or optional alodine coating.

Skins are cleco’d in place using the supplied cleco’s and pliers. Then riveted together, using the supplied rivets and rivet gun.

Solid riveted parts come pre-built from the factory to simplify the overall build process.

“FunFly Aerosports provide easy to assemble kit aircraft. The Savannah is an award winning Best in Class for both the Kit and Ready to Fly models”

Get In Touch

info@funflyaerosports.ie